China is by far the lowest cost producer for graphite electrode, followed by India. While the biggest consumer by far is also China, with at least of 60% of the market.

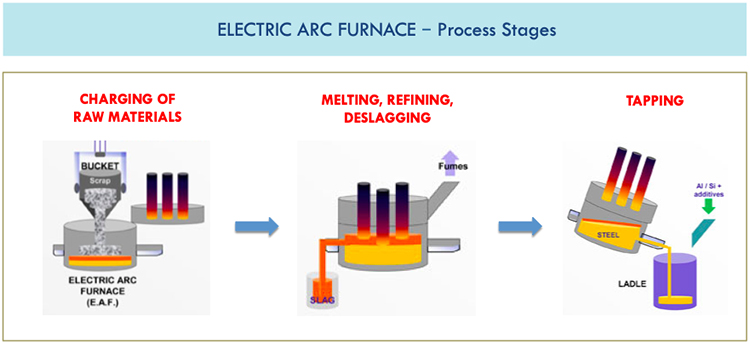

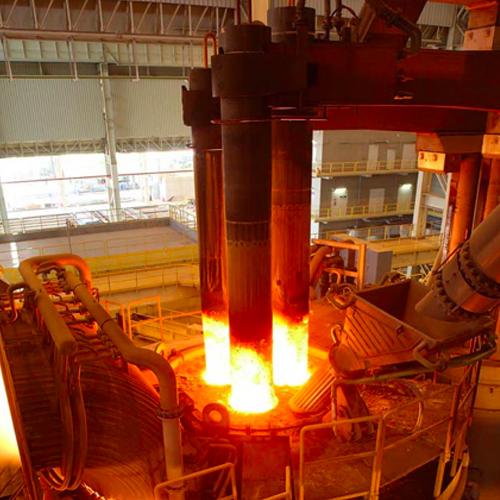

electric-arc furnaces (EAFs) are the biggest consumers of graphite electrodes , followed by ladle furnaces.

That is because, EAFs smelt steel scrap while ladle furnaces are used to raise the carbon content of steel.

Graphite electrodes are indispensable in EAF steelmaking, which is often a more efficient and cheaper alternative to blast-furnace steel making, but this is dependent on energy costs.

EAF steel making involves using recycled steel scrap and emits much less CO2 than a blast furnace, making it the more environmentally favorable choice for producing steel.

EAFs need electrodes of large diameter and high quality, otherwise they break when conducting electric current.

In contrast, ladle furnaces usually operate with an electrode diameter of less than 300mm.

By country, the biggest consumer by far is China, with at least 60% of the market.

About 80% of Indian production is consumed domestically.

Changes in the graphite electrodes market can be roughly linked to movements in the crude steel market.

While the size of the markets in China and India have significantly increased in volume year-on-year so far in 2019, they have shrunk slightly in the US and Europe.

shengmiao

Harm of too high temperature: when molten steel out of cooper mold, the billet shell is thin and easy to break out; The accelerated erosion of refractory can ea

shengmiao

1. The barrier function (mainly completed by the liquid slag layer) isolates the contact between air and molten steel, blocks the secondary oxidation of molten

shengmiao

In continuous casting, low corrosion resistance often occurs, which directly leads to uneven composition and will eventually affect the smelting quality. In or