Continuous casting processAfter the molten steel produced by the converter is refined in the refining furnace, the molten steel needs to be cast into billets

Continuous casting process

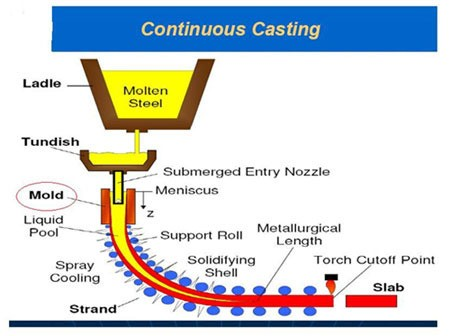

After the molten steel produced by the converter is refined in the refining furnace, the molten steel needs to be cast into billets of different types and specifications. The continuous casting section is the production process of continuously casting the refined molten steel into steel billets. The main equipment includes a turntable, a tundish, a mold, and a tension leveler.

Continuous casting process

The ladle containing refined molten steel is transported to the turntable. After the turntable rotates to the pouring position, the molten steel is injected into the tundish, and the tundish distributes the molten steel to each mold through the nozzle. The mold is one of the core equipment of the continuous casting machine, which makes the casting shape and rapidly solidify and crystallize. The tension leveler and the crystal vibration device work together to pull out the castings in the crystallizer, and cut them into slabs of a certain length after cooling and electromagnetic stirring.

The automatic control of continuous casting mainly includes control technology of continuous casting machine drawing roll speed control, mold vibration frequency control, and fixed-length cutting control.

shengmiao

Harm of too high temperature: when molten steel out of cooper mold, the billet shell is thin and easy to break out; The accelerated erosion of refractory can ea

shengmiao

1. The barrier function (mainly completed by the liquid slag layer) isolates the contact between air and molten steel, blocks the secondary oxidation of molten

shengmiao

In continuous casting, low corrosion resistance often occurs, which directly leads to uneven composition and will eventually affect the smelting quality. In or