This article mainly introduces the relationship between the mechanical strength and the temperature of graphite electrode and analyzes the reasons for the change.

The reason why the mechanical strength of graphite products increases with the increase of temperature

Relationship between mechanical strength and temperature of graphite electrode

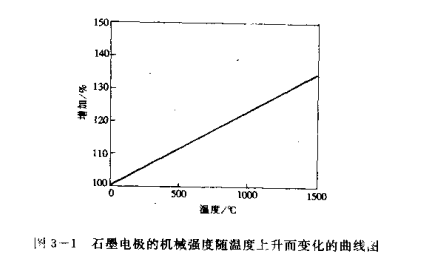

From normal temperature to 2500℃, the mechanical strength of graphite electrode increases with the rise of temperature. At 2500℃, the mechanical strength is about 1-2 times that of normal temperature. Figure 3-1 shows the curve of the mechanical strength of graphite electrode using petroleum coke as raw material changing with the rise of temperature (0-1500℃).

The reason why the mechanical strength of graphite products increases with the increase of temperature can be explained as follows: 1. Graphite products do not produce local plastic deformation at low temperature, so even if a relatively low load is given, the stress concentration will cause the fracture.

However, when the temperature rises to a certain degree, due to the appearance of a plastic state, local deformation is generated near the stress concentration point, the stress is dispersed, even if a relatively large load is applied, will not cause the fracture.

2. Due to the linear expansion coefficient of graphite crystal is larger anisotropy, after being cooled from high temperature can produce larger stress within the grain, due to the external force superposition of internal stress value is bigger, the strength of the low temperature when the graphite is low, but when heated to a certain temperature gradually reduce internal stress, so the mechanical strength increases with temperature rise.

【Carbo Graphite Industrial PTE. LTD.】

Carbo Graphite Industrial PTE. Ltd. is one of the leading group companies in China that produces and operates carbon metallurgy materials products, providing quick quotation, reliable quality and competitive price products and delivering services as quickly as possible in accordance with industry standards and customer requirements.

It was founded in zhengzhou, central and eastern China, in 1992.

In order to play a greater role in the entire production and supply chain, we work closely with our customers.

With more than 20 years of experience and expertise in the carbon metallurgy industry, the company is committed to research and development and provides a range of high-quality, innovative, cost-effective carbon and metallurgical products and solutions.

At present, the main products are graphite electrode, electrode paste, forged petroleum coke and refractory.

The product line includes carbon materials, graphite materials, refractories and water treatment materials.

Annual output of 200,000 tons of electrode paste (sealed paste), 50,000 tons of graphite electrode, 250,000 tons of calcined coke, 20,000 tons of refractory materials, etc.

We have great advantages in the production of electrode paste and graphite electrode.

Interested partners are welcome to contact us at any time

Carbo Graphite Industrial PTE. LTD. (our company specializes in producing and selling electrode products: electrode paste, sealed paste, Graphite electrode, etc.)

Contact person: Andy Lou

Telephone: +86 15290889928 (same number as WeChat & WhatsApp)

Chinese website: cn.chinacarbo.com

English website:www.chinacarbo.com

shengmiao

Harm of too high temperature: when molten steel out of cooper mold, the billet shell is thin and easy to break out; The accelerated erosion of refractory can ea

shengmiao

1. The barrier function (mainly completed by the liquid slag layer) isolates the contact between air and molten steel, blocks the secondary oxidation of molten

shengmiao

In continuous casting, low corrosion resistance often occurs, which directly leads to uneven composition and will eventually affect the smelting quality. In or