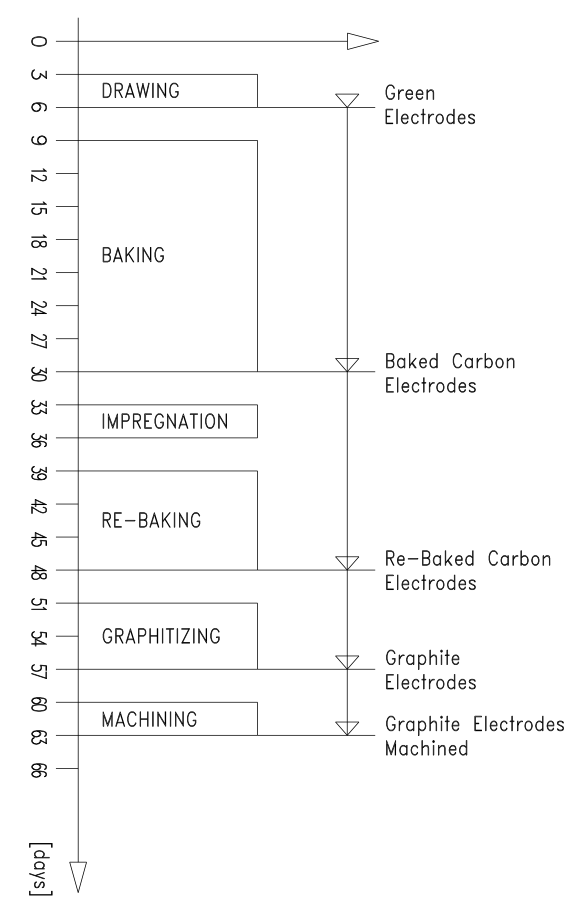

From Mixing to Machining the production of graphite electrodes takes about 60 days

The whole production process for graphite electrode includes RAW MATERIAL, MIXING, EXTRUSION, BAKING, PITCH IMPREGNATION, PREBAKING, GRAPHITIZATION, MACHINING.

Raw materials proportion in graphite electrodes:

1, Coke (approximately 75-80% in content)

Petroleum coke is the most important raw material. The highly anisotropic needle coke, due to its structure, is indispensable for the manufacture of high-performance electrodes used in electric arc furnaces

2, Pitch as Binders (approximately 20-25% in content)

shengmiao

Harm of too high temperature: when molten steel out of cooper mold, the billet shell is thin and easy to break out; The accelerated erosion of refractory can ea

shengmiao

1. The barrier function (mainly completed by the liquid slag layer) isolates the contact between air and molten steel, blocks the secondary oxidation of molten

shengmiao

In continuous casting, low corrosion resistance often occurs, which directly leads to uneven composition and will eventually affect the smelting quality. In or