DescriptionSlurry pump belongs to centrifugal pump in terms of working principle. Conceptually, it refers to a machine that increases the energy of solid and li

Slurry Pumps

Description

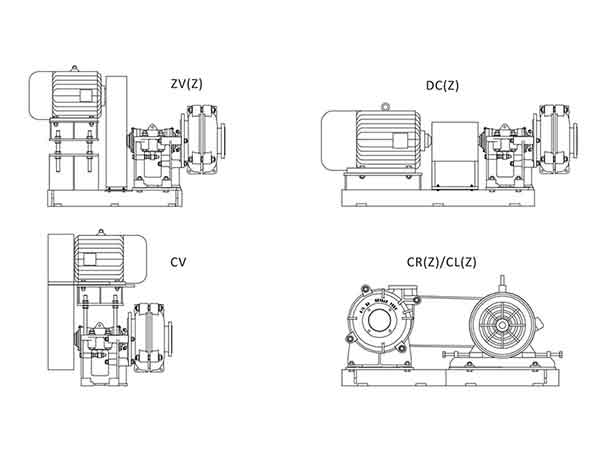

Slurry pump belongs to centrifugal pump in terms of working principle. Conceptually, it refers to a machine that increases the energy of solid and liquid mixed medium by means of centrifugal force (the rotation of the impeller of the pump), and converts electrical energy into A device for the kinetic and potential energy of a medium. At present, it is one of the indispensable equipment in various technological processes of mineral processing and coal preparation plants. Mainly used in: mining, power plant, dredging, metallurgy, chemical industry, building materials and petroleum and other industries. The name of the slurry pump is a centrifugal pump from the perspective of conveying medium. In addition, the slurry pump can be divided into different types from different angles.

Technical Parameter

| Name | Diameter | Flow Rate | Total Head | Applications |

|---|---|---|---|---|

| Heavy Duty Pump | 1″-18″(25 – 450mm) | 4-5400(m3/h) | 5-75m | Mainly used to handle the most abrasive and dense slurries inmetalliferous mining, coal mining, electric power plants, and building materials industries. Description: Horizontal, single-suction, single-stage, cantilever, double-casing,centrifugal pumps. |

| Light Duty Pump | 20 – 650mm | 3-12000(m3/h) | 4-60m | Used in mild erosion wear applications with lower-viscosity slurries in the metalliferous mining, coal mining, electric power plants, and building materials industries. Description: Cantilever-type, horizontal centrifugal pumps rated at high flow rate. Small-volume design takes up little place. The frame plates are interchangeable with wear-resistant metal plates or rubber liners. |

| Heavy duty High Speed Pump | 1″- 6″(25-150mm) | 16-1125(m3/h) | 12-95m | Mainly used to handle highly abrasive and high-viscosity slurries in themetalliferous mining, coal mining, electric power plants, and building materials industries. Description: Horizontal, single-suction, single-stage, cantilever, double-casing,centrifugal pumps. |

| Heavy-Duty High-Efficiency Slurry Pump | 40-300mm | 4-2333(m3/h) | 9-133m | Designed for handling mixtures that contain abrasive and corrosive solids in electric power plants, metalliferous mining, coal mining, constructional material and chemical industries, especially for the removal of ash and sludge in electric power plants. Description: Horizontal, single-stage, single-suction, cantilever, double-casing, high-efficiency centrifugal pumps. |

| Brand-New Model Pump | 2″- 6″(50-150mm) | 20-170(m3/h) | 5-75m | Popular uses of the pump are in minerals recycling, mine dewatering, coal washing, and feeding slurries to hydrocyclones or pressure filters. Description: Single-stage, single-suction, cantilever, and horizontal slurry pump provided with high-efficiency vanes. The pump delivers more than 10% higher pumping efficiency than the MA pump under the same working conditions. |

| Slurry/Dredging Dual-Purpose Pump | 4″- 14″(100 – 350mm) | 36 – 3000(m3/h) | 5-70m | This dual-purpose pump mainly used for dredging, water conservation, coal mining, and metalliferous mining tasks. Description: Single-suction, single-stage, horizontal, cantilever centrifugal pumps with wide flow passage. One-piece protective casing that is fastened in place by way of band clamps. |

| Vertical Submersible Pump | 40 -250mm | 17-1000(m3/h) | 4-40m | Model MV vertical pump is submerged in sump during use. It is commonly employed to deliver abrasive, high-viscosity slurries that contain large solids. Description: Slurry pumps without any shaft seal including the water seal. Parts that come into contact with the slurry are made of wear-resistant materials |

Comments: